Architectural Wood Doors

Appearance is determined by:

2. Glass in all or some of the panels

3. Door top: square top, arch top or radius top

4. Species of wood veneer -options at end of catalog

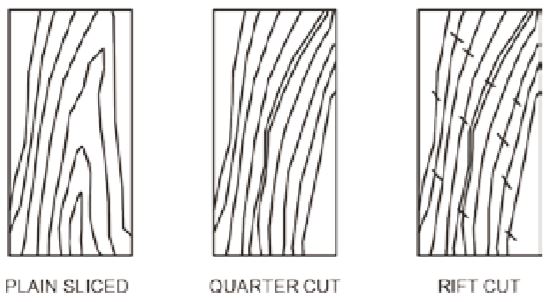

5. Type of veneer cut – see below

6. Matching of veneers -see below

7. Finish

Architectural Wood Doors

Architectural wood doors are engineered products and can be used in residential or commercial applications. These doors can withstand heavier hardware, but are more complicated to make. Our architectural wood doors are made with wood veneers. These veneers are made by thinly slicing lumber and pressing them onto a solid wood substrate or a core to make an engineered product.

Individual Veneer – Leaves are Cut from Lumber Veneer leaves are made by cutting through the wood in relation to the growth rings. The most common cuts are plain sliced, quarter cut and rift cut. Every species of tree grows differently and within the species each individual tree grows based on the climate it lives. Thus, the look of each veneer, even within species, is naturally different.

Plain Sliced – When slicing the veneer from the lumber, it is done parallel to a line through the center of the log. The pieces are kept in order of slicing and allows the veneer face to have a progression of natural grain.

Quarter Cut – The log is cut into four equal pieces (quarters) from top to bottom. Then, the plain sliced technique is used for each quarter. This creates a very straight grain pattern. Flecking is present in red and white oak wood species. Quarter cut is one of the most durable cuts in that it resists cupping and warping. Because of the way it is cut, there is less yield than one would have with same amount of wood plain sliced; therefore, it is more expensive.

Rift-Cut – Rift cut is used in oak species to decrease the flecking. The log is cut in four pieces like quarter sawn, but is then cut perpendicular to the radius rather than plain sliced; resulting in a tight and straight grain. This cut has the lowest yield and is the most expensive.

If Designing an Architectural Wood Flush Door the Adjacent Veneer Leaves are Then Matched

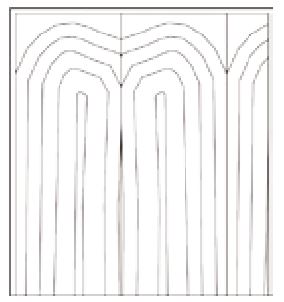

Book Match

For the wood grain to look like an open book or mirror image, every other piece of veneer is turned over. Book match is the most common type of matching. This matching can be used with all the above cuts and allows for the greatest amount of grain continuity.

One of the most common questions our customers ask: “Why is the stain not uniform?”. In book match, the symmetry is gained because you place the “tight” or smaller rings in close proximity and the “loose” or larger rings in close proximity. These two areas accept stain differently and reflect light differently. This phenomenon is known as the “barber pole effect” and is not considered a manufacturing defect.

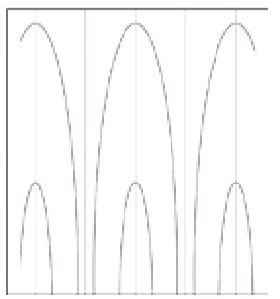

Slip Match

For slip match, every other piece is not turned over, but placed in precise sequence. There will be no “mirror or book match” effect. The pattern of grain will repeat, though. If using the cuts quarter or rift cut then slip match is the recommended match. While there is no barber pole effect as is seen with the book match, there can be a “sloping” effect with taller doors.

Plank Matched

Plank match is becoming more popular. The veneer leaves are from the same species but are not similar in color, grain or width. The leaves are specially selected. V-grooves can be applied between strips to simulate true planks of lumber.

Running Match

Leaves are placed together in running order without attention to matching the width of the pieces all the way across. The inner pieces will be the same width, but the outer pieces will likely not be. This match produces a non-symmetrical appearance in the veneer face, but has the highest yield and is the least expensive.

Balance Match

All of the leaves in the panel are of equal width. This match produces a symmetrical appearance, but results in a lower yield.

Center Balance Match

Each veneer panel has an even number of leaves that are the same width. This results in joint line in the middle with a symmetrical appearance and is of the lowest yield.

Wood Door Construction

Wood: We use the finest wood stock available. Each piece of our stock is hand selected to coordinate color and grain. Rustic style doors, made with knotty alder or knotty pine show variations like mineral streaks, sapwood, heartwood, and some knots. Knots will be structurally sound, but could have slight voids or cracks around them.

Doors: Stile-to-rail joints are doweled and glued with marine rated glue to ensure a strong, warp-free precision joint. Raised

Wood Panels: Panels are 1-11/16” thick inset into 3/8” groove in moulded stiles and rails with a 3/8” thick panel tongue. All wide panels are edge glued using machined glue-joint construction with marine rated glue to increase strength and inhibit warping. Clearance between panel edge, stiles, and rails is maintained at 1/16” to prevent warpage due to normal wood expansion. The Gravley standard profile is used to machine panels, stiles, and rails. We have many other profiles in stock or we can make your unique profile.

Raised Decorative Moulding: For the raised moulding option, we use 3/4” x 1-1/4” moulding machined to the Gravley standard profile and fitted to all door contours. We have many other profiles in stock if desired.

Glass: All lights are true divided. Glass stops are recessed into stiles and rails to create a precision, crack-free appearance. All door glass is tempered for safety. Double insulated glass is available in many different types. Art Glass can be triple-insulated if desired.

Frames: We build frames to match our custom doors. All thresholds and seals are premium quality. On thicker and heavier doors we use premium ball bearing hinges for ease of opening and durability.

Warranty: Gravley Doors has a two-year limited warranty on all doors.